|

Hangzhou powerkey industries and trade co., Ltd

|

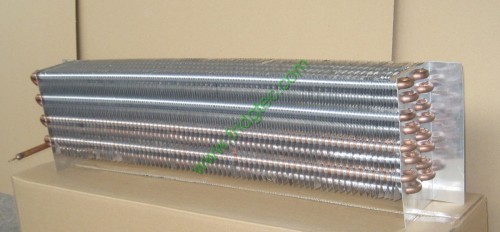

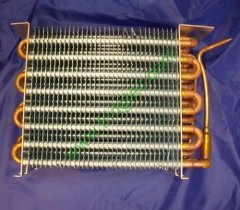

Good quality aluminum finned copper tube evaporator for refrigeration cold storage

| Price: | 1.0 USD |

| Payment Terms: | T/T,L/C,D/P |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

High quality mechanical expanding between copper tube and fins, tight contacting andoptimized heat exchangin

Good quality aluminum finned copper tube evaporator for refrigeration, cold storage

Factory introduction

Our factory located in Hangzhou,China,10 minutes car distance to our office.

Our factory is ISO 9001 certified, professional in production of copper tube fin evaporator and condenser.

We use high quality material, equipped by high automation machinery like fin punching machine, auto tube flaring machine, automatic welding machine, we have over 15 years experience in production and with professional technicians to control mold production, IQC, IPQC, FQC and OQC, all products comply withJapan&Italystandard.

Typical benefits and character

Well distributed liquid dispensing of windward area of condenser coil

High quality mechanical expanding or super high pressinghydraulic expanding between copper tube and fins, tight contacting andoptimized heat exchanging.

Free pitch distance selection, reduce the frost affection in low temperature.

With single or double reverse-flow system, small water resistance, good heat exchanging

With super high temperature vacuum drying, ensure inner without impurity or water substance.

Main application & usage

Products are suitable for R134A, R22, R404A, R407C, and CO2 refrigerant.

Widely used for commercial refrigerators and freezers, commercial showcase cabinet, air-conditioning systems, dehumidifier, ice maker etc.

Material: copper tube, aluminum fins, galvanized steel bracket if need

- Copper tube: made by HailiangChina,Φ5,Φ7mm,Φ7.94,Φ9.52, Φ12.7, Φ15.88, inner thread groove or smooth tube

- Aluminum foil: blue or other color hydrophilic or uncoated bare

- Fin type: louver, flat, corrugated or slit fin

- Side plate: galvanized steel plate, stainless steel, aluminum or brass.

Production process:

Tube bending, punching fin, tube expanding, fins installation, drying, welding, leakage test, tube bending, quality inspection, packing